Capabilities

Capabilities

Ink and Solution Development, High-Throughput Fabrication, and Scaling Studies

Laboratory

National Renewable Energy Laboratory (NREL)Capability Expert

Scott MaugerClass

BenchmarkingCharacterization

Process and Manufacturing Scale-Up

Node Readiness Category

1: Low-Temperature Electrolysis (LTE)2: Photoelectrochemical (PEC)

Description

Previous capability name: "High-Throughput Approaches to Scaling New PEM Electrolysis Electrodes Using Relevant Production Technologies."

Catalyst ink and ionomer dispersion formulation, high-throughput fabrication, and scaling studies are recognized core competencies at NREL. We have been working on optimizing inks for new catalysts and electrode layers for several years. We have also significant knowledge in ionomer dispersions for catalyst ink or membrane casting. We have the equipment, expertise, and methodologies to formulate and fabricate these multicomponent dispersions, study the effects of catalyst and support composition, ionomer type, solvent, and mixing parameters, and characterize both the micro/nanoscale colloidal properties and the macroscale fluid properties of the dispersions via light scattering, static and dynamic contact angle, zeta potential, and steady and oscillatory shear rheology (Figure 1). We have also developed and implemented small-scale processing capabilities for fabricating catalyst layers (Figure 2) on a variety of substrates and casting membranes. FCTO-funded capabilities include ultrasonic spraying (Figure 3), knife, bar and rod coating. The lattter two of which enable coating of 100s cm2 in seconds. However, we can leverage other NREL-internal capabilities such as inkjet and aerosol spray (Figure 4), and slot die sheet coating.

Given an understanding of dispersion properties and process parameters at a small scale, we can then use a multi-technology roll-to-roll (R2R) coating station with multiple coating technologies (slot die, gravure and multilayer slide die) to perform high-throughput fabrication of electrodes and membranes and extend our understanding of material-structure-process relationships to scalable processes. This high-throughput capability enables many-meters-in-length production of electrodes or membranes of different composition, and comparison of the process parameters and resulting morphology based on several types of relevant deposition processes.

NREL’s capability is relevant to PEM and AEM water electrolysis, PEC, and SOEC systems. Proven protocols and methodologies developed for PEM systems can be leveraged for these newer or less-studied systems. In addition, NREL’s capability is being leveraged under the H2NEW and M2FCT Consortia, showing relevance to those related material sets.

Capability Bounds

For ink formulation research only small amounts of materials are needed, e.g. 100 mg of catalyst can be used for Zeta potential and dynamic light scattering measurements of many different formulations. Rheology measurements require a few hundred milligrams to a few grams of material. Small-scale electrode fabrication requires a few hundred milligrams of material. NREL’s current capability enables many-meters-in-length production of electrodes of different composition, and comparison of the process parameters and resulting structures based on several types of relevant deposition processes. R2R coating experiments require grams of catalyst or ionomer materials. These are all laboratory-scale capabilities with no pertinent bounding limitations.

Unique Aspects

These capabilities reflect NREL’s core competencies in process science, materials integration, and scale-up. The breadth and scale of deposition capabilities as well as capability experts’ background in industrial R2R processing and colloid science is unique.

Availability

There are no pertinent use limitations. Some of the capabilities are in the NREL Energy Systems Integration Facility, a user facility where external researchers can apply for access to facilities and equipment.

Benefit

Integrating novel materials into devices requires expertise and specialized equipment for component fabrication that are unique from the the discovery and synthesis aspects of the materials themselves. Capabilities and methodologies are required to fabricate electrodes and membranes on relevant substrates and using relevant processes in ways that enable high-throughput evaluation of matrices of dispersion, electrode, or membrane compositions and structures. This would enable accelerated evaluation of electrode ink or ionomer dispersion composition and properties as well as process parameters for optimal uniformity, performance and durability. In addition, a goal of HydroGEN is to advance materials scale-up and lower component costs at high volume production. The proposed capabilities are highly relevant to understanding and advancing high-volume production of electrodes, membranes, and electrochemical cells.

Images

Figure 1. a) Zeta potential measurements of IrOx and Pt on Vulcan carbon showing similar increase in electrostatic stability with addition of ionomer. b) Steady-shear rheology of IrOx catalyst compared to Vulcan carbon. Like carbon blacks, e.g. Vulcan, IrOx shows rheological properties of an agglomeration. c) Steady-shear rheology of IrOx catalyst as a function of ionomer:catalyst mass ratio. The transition from shear thinning (I:C = 0) to Newtonian (I:C > 0) shows that the ionomer is stabilizing the particles against agglomeration.

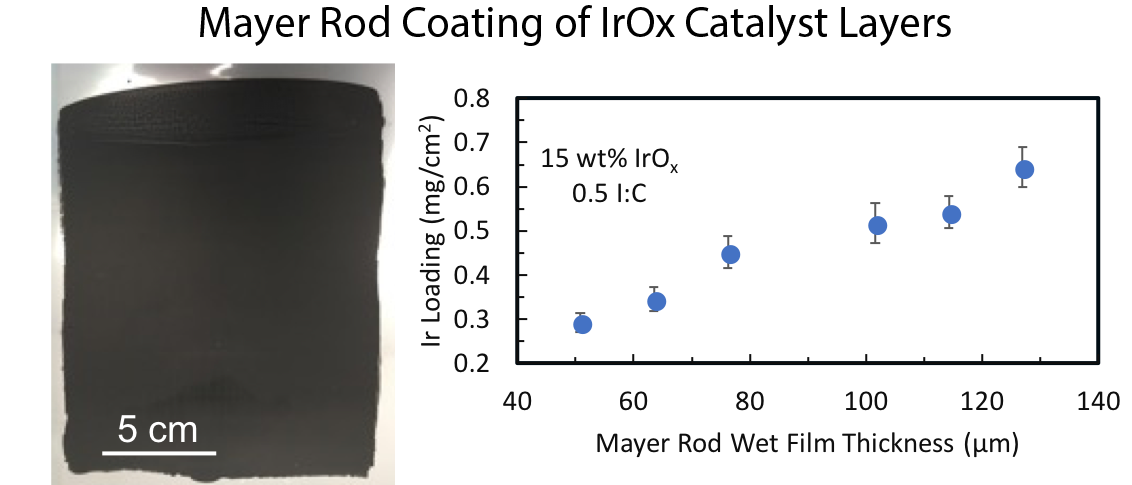

Figure 2. Small-scale Mayer rod coating of IrOx catalyst layers. The photo at left shows highly uniform electrodes are produced with this method. The plot at right shows a wide range of loadings are possible from the same ink formulation using different coating rods.

Figure 3. Ultrasonic spray system fabricating multiple electrodes.

Figure 4. Aerosol jet spray system.

Figure 5. Multitechnology coating station with slot die and microgravure coating ability, two oven sections and interleaf peeler.

References

Wang, M.; Park, J. H.; Kabir, S.; Neyerlin, K. C.; Kariuki, N. N.; Lv, H.; Stamenkovic, V. R.; Myers, D. J.; Ulsh, M.; Mauger, S. A. Impact of Catalyst Ink Dispersing Methodology on Fuel Cell Performance Using In-Situ X-Ray Scattering. ACS Appl. Energy Mater. 2019, 2 (9), 6417–6427. https://doi.org/10.1021/acsaem.9b01037.

Park, J.; Ulsh, M.; Mauger, S. A. Solvent Absorption Rate of Perfluorosulphonic Acid Membranes towards Understanding Direct Coating Processes. International Journal of Hydrogen Energy 2021, 46 (59), 30239–30245. https://doi.org/10.1016/j.ijhydene.2021.06.168.

Park, J.; Kang, Z.; Bender, G.; Ulsh, M.; Mauger, S. A. Roll-to-Roll Production of Catalyst Coated Membranes for Low-Temperature Electrolyzers. Journal of Power Sources 2020, 479, 228819. https://doi.org/10.1016/j.jpowsour.2020.228819.

Mauger, S. A.; Pfeilsticker, J. R.; Wang, M.; Medina, S.; Yang-Neyerlin, A. C.; Neyerlin, K. C.; Stetson, C.; Pylypenko, S.; Ulsh, M. Fabrication of High Performance Gas-Diffusion-Electrode Based Membrane-Electrode Assemblies. J Power Sources 2020, 450 (29), 227581. https://doi.org/10.1016/j.jpowsour.2019.227581.

Colón-Mercado, H. R.; Mauger, S. A.; Gorensek, M. B.; Fujimoto, C. H.; Lando, A. A.; Ganesan, P.; Meekins, B. H.; Meeks, N. D. Electrode Optimization for Efficient Hydrogen Production Using an SO2-Depolarized Electrolysis Cell. International Journal of Hydrogen Energy 2022, 47 (31), 14180–14185. https://doi.org/10.1016/j.ijhydene.2022.02.166.

Khandavalli, S.; Park, J. H.; Kariuki, N. N.; Zaccarine, S. F.; Pylypenko, S.; Myers, D. J.; Ulsh, M.; Mauger, S. A. Investigation of the Microstructure and Rheology of Iridium Oxide Catalyst Inks for Low-Temperature Polymer Electrolyte Membrane Water Electrolyzers. ACS Appl. Mater. Interfaces 2019, 11 (48), 45068–45079. https://doi.org/10.1021/acsami.9b14415.